The XD-120 soap stamping machine is a versatile and efficient solution for high-quality soap production. This advanced machine combines soap stamping and printing functions in one compact unit, helping manufacturers achieve a seamless production process. Focusing on precision, durability and user-friendly operation, the XD-120 increases production efficiency while maintaining excellent product quality.

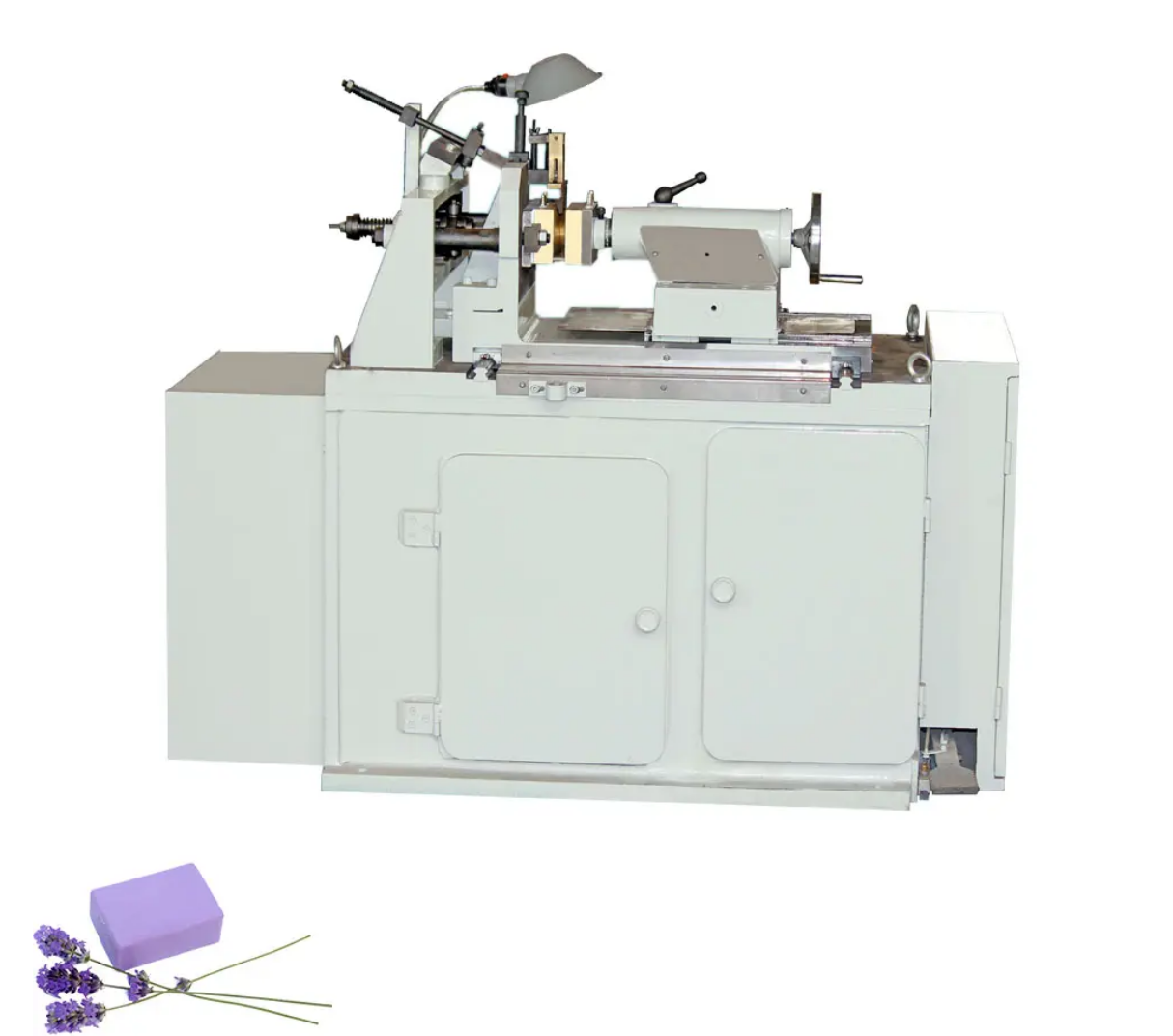

XD – 120 Soap Stamping Machine

Product Detail

Overview

The XD-120 Soap Pressing Machine is an upgraded version of the popular XG-01 model. It features a crankshaft drive mechanism that replaces the traditional cam drive—significantly reducing vibration and noise while enhancing production efficiency and machine longevity.

Seamlessly integrated with the SDJ two-stage vacuum plodder, it forms a continuous and automated soap production line, fully meeting the requirements of modern soap molding processes.

Efficient Production

High Production Speed

Capable of pressing 80–120 soap bars per minute, significantly boosting output to meet growing market demands and expand production capacity.Fully Automatic Operation

Advanced automation minimizes manual intervention, streamlines the workflow, lowers labor costs, and reduces human error—ensuring stable and consistent high-quality production.

Superior Quality Assurance

Precision Embossing

High-precision molds ensure that each soap bar meets professional standards in shape, size, and embossing detail—resulting in a flawless finish.High-Resolution Printing

Advanced printing technology allows clear, long-lasting images or text to be applied to the soap surface—enhancing both product aesthetics and brand value.

User-Friendly Design

Easy Operation

The intuitive digital control panel allows quick setup and operation, even for first-time users—saving time and training effort.Fast Changeover

Rapid mold and print-template switching reduces downtime and improves production flexibility.Low Maintenance Cost

With fewer moving parts, easy disassembly, and a durable structure, the XD-120 is designed for low total cost of ownership and long-term efficiency.

Durable & Reliable

Sturdy Construction

Built with high-strength, wear-resistant materials, the machine maintains excellent performance in long-term, high-intensity working environments.Long Service Life

Rigorously tested for stability and durability, reducing investment risk while maximizing output and return on investment.

Main Components

Stamping Unit

Precision molds ensure fine, consistent embossing on every bar of soap.Printing System

High-resolution print heads apply text or images with professional clarity.Control Panel

Digital interface for real-time parameter adjustment, monitoring, and diagnostics.Conveyor System

Durable and adjustable belt for smooth soap transfer through embossing and printing stages.

Working Principle

Soap billets are automatically fed into the stamping unit, where high-precision molds emboss each bar with detailed patterns. The embossed bars are then conveyed to the printing system, where high-resolution text or graphics are applied.

An integrated intelligent control system manages the entire process, ensuring consistent quality while minimizing waste.

Maintenance Recommendations

Regular Cleaning

Clean external and working surfaces regularly to remove soap debris and dust.Lubrication

Lubricate moving parts at regular intervals to ensure smooth, wear-free operation.Component Inspection

Periodically inspect components and replace any worn or damaged parts to maintain peak performance.

Main Technical Data:

Type: Electromagnetic Speed Regulation, reciprocating straight line, long bar stamping.

Capacity: 80 – 120pcs/min

Weight Of Soap: 50 – 250g

Reciprocating Stroke: 115mm

Power Consumption: YCT – 160 – 4B 3Kw 115 – 1150rpm

Overall Dimensions: (L×W×H) 3560×1410×1135

Gross Weight: 1950Kg

Why Choose the XD-120?

The XD-120 Soap Pressing Machine offers a winning combination of efficiency, durability, and automation—making it an ideal solution for both small-scale soap makers and large-scale industrial producers.

Invest in the XD-120 today and experience the difference in quality and productivity!

Wuxi Zhongtian Tolet Soap Complete Equipments Co., Ltd. is located in the south suburb of Wuxi, jiangsu. Wespecialize in the development of soap machinery and also engage in other aspects from production to providingtechnical support and spare parts. The products we supply are new generation of soap lines with advancedtechnology.

Our company can supply a complete set of soap production machine and matched equipment in capacity rangedfrom 1 000kg-6000kgh including the process of comsecutive saponification, refining, grinding, vacuum drying.pneumatic conveying, soap flake collection and shape stamping etc.

Contact us now for a quote or more information